Stop “Braking” my Heart.

Rim brakes, cable-actuated disc brakes, hydraulic disc brakes. For road bikes these are the three main types of brakes that you will see. Follow along as I go through each type and break down each and why they are important. But first:

- Rim brakes have been used on road bikes for many years now and until recently have been the norm on most all road bikes.

- 2012 was really the first hint that disc brakes were going to come on road bikes. This type of brake was new to road biking, and would require a few changes to frames and wheels.

- Cable-actuated disc brakes were first, quickly followed by hydraulic disc brakes. Mountain bikes have been using these for years and it’s finally come into the forefront on road bikes. The main differences between cable and hydraulic have been price and quality.

- But, there was also the question of “quick release” skewers and how they will play a roll in all of this. And also, what’s a thru axle?

Rim Brakes

Let’s start with Rim Brakes. Traditional single pivot (Campy style) or newer dual pivot (Sram/Shimano style) rim brakes attach to the frame and fork via a long bolt that passes through the brake with a recessed nut on the back to secure it to the frame or fork. Both front and rear brakes have a cable that runs from the brake lever to the caliper, then attaching to a pinch bolt which together operate the system.

Rim brakes work as follows: When you pull on your brake lever, this pulls the cable and closes the caliper, pressing the brake pads against the braking strip of your rim, creating friction and slowing you down. This system has worked great for a long time. The downside to riding on rim brakes (besides the lack of stopping power in wet conditions) is the fact that rim brakes wear down the side wall of your rims.

Manufacturers have built up extra thick “brake tracks” on the sidewalls to accommodate for this, but eventually it wears down. Small chunks of aluminum pieces from the rim or small pebbles can get stuck in the pads: this is something I find very often on bikes with rim brakes. Check your pads for these small pieces and pick them out, they will wear the side wall of your rim significantly faster than a clean brake pad and greatly compromises the stopping power of the braking system.  These little pieces, if left unattended, will wear grooves into your braking strip creating ridges like in a vinyl album. The problem with that is when you apply the brake pad, it’s not making full contact with the sidewall of the rim. Instead, it’s just grabbing the ridges, which doesn’t give you full power to stop the bicycle.

These little pieces, if left unattended, will wear grooves into your braking strip creating ridges like in a vinyl album. The problem with that is when you apply the brake pad, it’s not making full contact with the sidewall of the rim. Instead, it’s just grabbing the ridges, which doesn’t give you full power to stop the bicycle.

Disc Brakes - cable

Cable-actuated disc brakes. The next step in the braking evolution. These brakes are a big step up from rim brakes and will increase your stopping power. They will allow for better stopping power in wet or misty conditions and don’t wear down the sidewalls of your rim. Cable-actuated disc brakes are identical in the way that it works to the typical caliper road brake. There is a single pivot and a dual pivot option.

From the lever, the cable housing travels to the calipers, attaching to a pinch both that operates the system. The calipers are mounted on the non-drive side of the fork leg and the non-drive side of the chain stay in the rear. The single pivot option moves one pad and compresses the rotor against that pad and a stationary pad, creating friction and slowing you down. This system works great for most, and will continue to for many years. The pad service on these will be making sure that the pads have enough material on them to stop you and its not metal on metal. One thing to make sure of with these brakes is that your rotor is within at least one millimeter from the stationary pad without rubbing while riding.

Having the rotor this close will allow for the best contact with the pads and not bend your rotor unnecessarily. The dual pivot option moves two pads simultaneously, sandwiching the rotor between the two pads, creating friction and slowing you down. This system is the best of the cable-actuated disc brake systems, since it applies force to both sides of the rotor evenly. The service on the dual pivot is the same as the single pivot (except for the fact that your rotor will need to be centered between both pads to ensure even contact).

Disc Brakes - hydraulic

The ultimate in stopping power, modulation and control is hydraulic disc brakes. Mountain bikes have been using these for years and it’s finally come into the forefront on road bikes. Hydraulic disc braking systems offer the best stopping power by displacing fluid from the brake lever and actuating the disc caliper (similar to what happens in your car).

With this system, you can safely operate the brakes and control the levers with one finger. This is by far the best system for people with smaller hands or folks that are very timid descenders. Since there is no friction built up from the cable running through the housing, the amount of force needed to engage the brakes is far less, resulting in a much smoother operation. With this system there are no issues with brake cables and housing being contaminated from riding in dirty or wet conditions (however the fluid can become dirty after so long from brake dust creeping in from the pistons).

When filling the braking system with the recommended fluid (called “bleeding”), the number one goal is to eliminate all air bubbles from the system, creating a solid stream of fluid. If there is air is in your hydraulic brake system, it will make your brakes feel “spongy” or unresponsive. The hydraulic disc brake caliper moves two pistons simultaneously and sandwiches the pads against the rotor. The hydraulic brake requires the rotor to be “true,” since the area in between the pads is very tight. If the rotor is not true, you will hear a “shing” noise every time the rotor makes a revolution.

With the hydraulic system, you will need to bleed or replace your fluid once a year to ensure that you have no air or contaminates in the system. The wear on your pads will need to be monitored in the same fashion as a cable-actuated system, but when it comes time to replace the pads both pistons will need to be reset, as well as if you take your wheel out of the bicycle and accidently squeeze the lever.

With both styles of disc brakes, it’s important to make sure that no chain lube or oil gets on your rotors or embeds itself in your brake pads. I recommend never touching the part of the rotor that engages the pads, as oils on your hands can cause contamination. If your pads have been contaminated, you will feel the loss of stopping power immediately. There will most likely be a loud howling associated with that. As a side note, disc brakes will howl when wet as well, but that disappears as soon as they dry.

QR vs TA

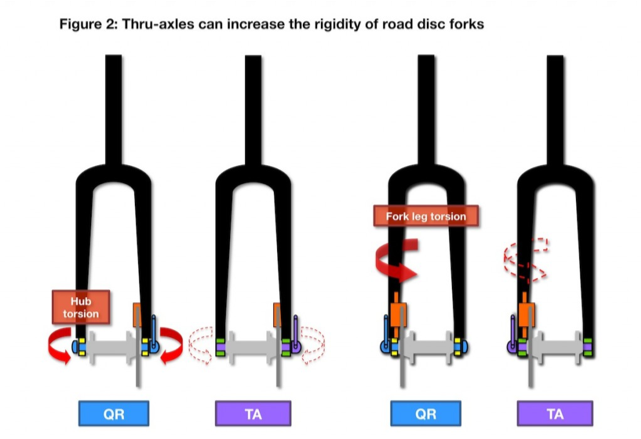

I mentioned “quick release skewers” and “thru axles” in the beginning. I’d like to share the benefits of both very quickly. Disc brakes initially came out on road bikes with a quick release option. For the most part this works, however the quick release can never really align the hub back into the drop outs the same, and never really hold the wheel tight enough. This allows the rotor to move or “flex” between the pads, potentially causing some rubbing issues. Hydraulic braking systems with skewers notice this more since the tolerance between the pads and the rotor is so tight.

Over the last couple of years, the bicycle industry has decided on using a 12mm diameter thru axle instead of a 5mm diameter quick release. They have also decided to stretch out the rear end of the bike to 142mm (instead of the previously used 135mm disc brake spacing).

A “thru axle” inserts the same as a quick release skewer, but instead of having a nut to put on the other end, the threads are part of the frame/fork and sandwich the hub together. This allows the hub to have a bigger surface to rest on and stiffens up the interface between the hub and the bicycle frame/fork. This does two things: first it stiffens up the hub allowing you to be more efficient with your power transfer into the bicycle and secondly it allows for better descending control since it’s predictable.

As we move farther with model changes and different genres of riding within the road category, you will notice a sharp decrease in the rim style brake bikes being offered. This will also be true for cable actuated disc brakes: especially the single pivot offering. These will be found on very entry level road/gravel/cross type bicycles. As hydraulic operated systems continue to decrease in price, and ways to “bleed the system” becomes faster and easier, you will notice a growth of hydraulic offerings on bikes.

If you are planning to buy a disc brake bicycle now or very soon, make sure that is has front and rear 12mm thru axles, with a 142mm rear end. If not, replacement options will be extinct very shortly. Disc brakes are newer to road bikes, and the current standard is a 142mm rear end and 12mm thru axle. Make sure that any bike you are thinking of has that standard. It will benefit you in the long run. -Devin Bovee