Rear derailleurs are impressive pieces of machinery. They eloquently move the chain from cog to cog with an effortless swing of the lever, or at least that’s what we want it to do! Parallelograms, pulleys, cable tension, cable and housing wear, derailleur hanger alignment along with many other factors affect the performance of your rear derailleur. It’s a simple, but very complex component controlled by a 4mm stainless steel cable and a lever.

It’s a simple, but very complex component controlled by a 4mm stainless steel cable and a lever.

What causes bad shifting? Here are some basics.

Cables and Housing. When you swing the shift lever, in return you are pulling on a cable. The derailleur reacts, and moves a pre-determined distance based on brand and gearing. The same principle is applied when you release the cable, shifting into a higher gear. If the shift cable and housing are old and worn, this movement will not be easy.

Friction from dirt and everyday road debris will penetrate the housing through the ferrules, and embed itself between the cable and inner liner of the housing. Multiply that with the normal friction that occurs from rubbing a metal cable within a plastic sleeve and that’s how your cables become worn out, and your shifting can become inconsistent. Shift cables can also start to separate from the head and become lodged within your shifter, creating a rat’s nest.

The rule of thumb is to replace your cables and housing every year. Always try to replace with a “Low-friction” cable and housing (brands like SRAM, Shimano, and a few others offer this) Your local bike shop will always have these in stock. Keep your shift cables clean and lubricated to increase performance and reduce friction even farther. Remember: friction is our enemy when it comes to shifting.

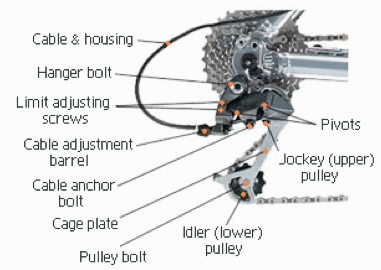

Cable Tension, Hanger Alignment, and Limit Screws. Hanger alignment is the most important piece of this equation. Without it, your limit-screw adjustments, cable tension and other adjustments will not be correct. The hanger aligns the derailleur with the cassette and the wheel, allowing the derailleur to shift properly throughout the gear range. This adjustment is made by using a hanger alignment gauge. Limit screws tell the derailleur where to stop. There is a screw forcing it to stop before it hits your spokes, and there is a screw stopping it from getting stuck between the high gear and the frame.

The most overlooked limit screw is the B Tension screw; this creates or removes a gap between your cassette and your jockey pulley. Cable tension is easily adjustable. If your cable tension is off, your shifting will be inconsistent; too tight and shifting into high gears will suffer by not dropping onto the next gear, too loose and shifting into low gears will be tough and require two clicks to move it up the cassette.

Finding the correct cable tension is important and requires practice. A one quarter turn of the barrel adjuster can affect quality of your shifting in a big way. Be gentle with the barrel adjusters when adjusting and use them in very short increments. Try and keep the cable tension tight enough to move up a gear but loose enough to allow the spring in your derailleur to close and move the chain down one gear on the cassette.

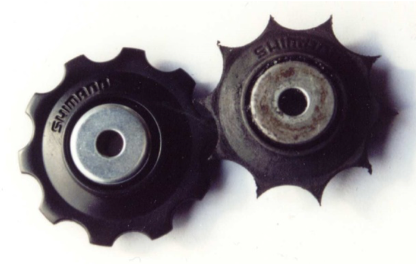

Worn Cassette, Pulleys, Chain, Pivots, Shifters. Worn parts are exactly that! Replace them. Worn parts can cause harm to us and others around us, so be responsible and replace your parts in a timely manner.

Don’t think you can get another few years on that chain because you probably can’t. When the chain becomes worn it does not engage with cassette fully, and can slip when applying a good amount of force (like climbing up a hill, or taking off from a stop light). When you use a chain for too long, you will wear down the cassette and the two will “mate,” causing terrible shifting when a new chain is installed.

Cassettes will also become worn from riding: typically we recommend replacing your cassette after the life of two chains. However, if you let your chain go for too long the cassette will need to be changed as well. There are many other reasons bikes shift poorly (like neglecting the small stuff). Keep in mind that pulleys can crack, or become sharp on the teeth like a ninja star. They will not move the chain correctly between the gears once worn. Pivots become loose from using your derailleur.

Looseness or “slop” in the pivots will affect the indexing making for inconsistent shifting. When the looseness in the pivots is detected, there is no fix but to replace the derailleur: this usually means you have gotten many thousands of shifts out of it and its lived its life. You can help extend the life of these pivots by keeping them clean and well lubricated. Shifters are mechanical pieces and require service just like any other moving part of your bicycle. Keep the shifters clean by peeling back the hoods and opening the levers, exposing the mechanical pieces inside. Spray a good degreaser in there and then lube the moving parts using a lightweight oil (like Phil’s Tenacious oil or even Tri-Flow).

Treat each component right and it will treat you that way in return. Keep in mind that bikes are machines and need service just like your car. There are “normal” lifespans of components, and they should be monitored.

This is a very general overview of what can happen and some ways to fix issues. I will dive deeper into each part in later entries. If you ever have any questions I am always available via phone, email or in-store, thank you!

-Devin Bovee 559.797.0148 Devin@stevensbicyles.com